ROPE For Window Cleaners

Types of Window Washing Rope

The first important thing to cover is the various types, or constructions of rope. These will affect the rope's performance and dictate which gear, such as descenders and rope grabs, will be compatible with the rope. There are other types of rope available, but these are the ones you'll come across for high risk window cleaning and rope descent work.

3 Strand

One of the oldest styles of rope in the world is 3 Strand rope. Essentially, it's three large bundles of fiber wrapped around one another. 3 Strand rope has a large texture that is easily seen and felt. The three strands are customarily woven tightly around each other, but by twisting the rope, you can work it apart and see they are three separate divisions.

This type of rope is often considered "old school" and is only available in large diameters like ⅝" (16mm) or larger (anything less than ⅝" is uncommon in window cleaning rope access equipment). 3 Strange rope has limited options for compatible equipment and is commonly used as a backup line by people working on swing staging. It's pretty uncommon for full rope descent systems to see 3 Strand rope.

Solid Braided

Solid braided ropes, like those from Sky Genie, are frequently seen in use with cylinder descenders. They are a soft rope, and many people think of them as mushy. They have a great hand and can tie very tight knots. Generally, they work well with friction-based descenders and grabs that don't rely on pinching the rope. Since solid braided ropes are mushy and don't maintain roundness well, cammed devices are not ideal.

Solid braided ropes are popular because of their low cost and great feel but can limit what gear you can use with them.

Double Braided

Initially from the arborist industry, double braided ropes have an easily felt bumpy texture. This makes them ideal for use with prusiks , which are common in the arborist industry. Window cleaners don't use prusiks, but many have discovered that this type of rope goes well with a rope descent set up.

The most common double braided rope in window cleaning is New England Teufelberger Safety Blue. While not actually blue, Safety Blue is named for its bright blue core. To assist with inspections, when you start to see blue showing through, you know that the outer bundles have become worn and that the rope is ready to be replaced.

Kernmantle

Kernmantle rope is the newest type of rope and has the highest performance of all rope used for window washing. Kernmantle rope is made from two parts, the kern or core and the mantle or sheath.

The core carries most of the rope's strength and is a significant factor in how much the rope stretches. In dynamic rock climbing ropes, the core is woven in a criss-cross way allowing for more stretch. In industrial ropes, the core is nearly straight, giving it a very low stretch.

The sheath is composed of small bundles of fibers wrapped around each other and the core. These bundles are called carriers. It's a bit counterintuitive, but the more carriers you have, the thinner your sheath. This makes the ropes feel smoother and have a better hand but compromises durability. The fewer carriers you have, the more durable the rope, though you give up softness and feel.

Far and away, the most common rope in window cleaning is New England Teufelberger KMIII (pronounced K M 3). It's a "middle of the road" rope in terms of hand and durability. The sheath has 32 carriers giving it a good compromise between feel and endurance.

Kernmantle rope is the gold standard for high rise window cleaning and rope descent and is the only rope you will find in rope access. It maintains its roundness, so it's ideal for use in cammed devices, giving it the widest assortment of compatible devices of any rope.

Material

There are two primary materials you will find in window cleaning rope access equipment: Nylon and Polyester. The difference between these materials that matters for rope descent is their stretch. Polyester has less stretch than Nylon, so all things being equal, a polyester rope will be less stretchy than a nylon rope. In general, the less stretch, the better. (So long as the overall rope is static or low stretch, it's acceptable for high rise window cleaning, so no need to avoid Nylon!)

Ropes are manufactured from 100% Nylon, 100% Polyester, or a combination. For example, KMIII is a combination that has a polyester stealth and a nylon core. There are numerous engineering reasons why Teufelberger New England made those material choices but remember that the critical thing for window cleaning access equipment is that the more polyester in a rope, the less it stretches, and that's generally a good thing.

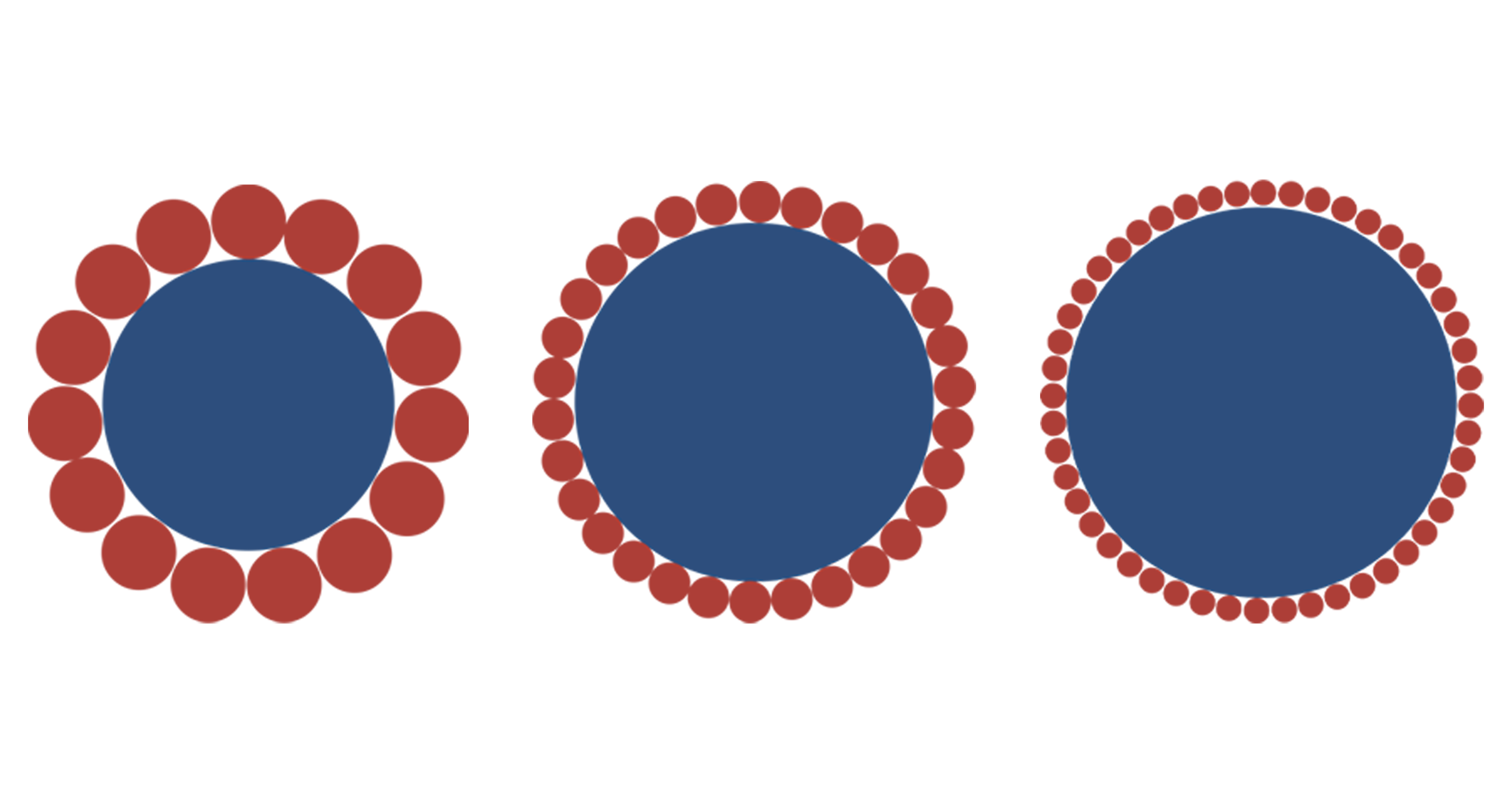

Stretch

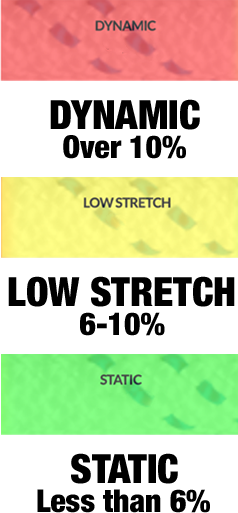

All rope stretches when you put force on it. How much it stretches is a factor of its construction, diameter, and material, amongst other things. Broadly, rope is broken down into Dynamic (for rock climbers, not window cleaning), low stretch, and static. Low stretch and static are both acceptable for window cleaning. In fact, many cleaners refer to low stretch and static together as simply static.

Rope stretch is calculated by looking at how much the rope stretches when 10% of its MBS is applied. For example, if a rope's MBS is 10,000 lbf, you'd put 1,000 lbf on it (10% of 10,000 lbf) and then see how it stretches. If you had a 100' rope and after you put the force on it, it stretched to 105', that would be 5% stretch.

Though any low stretch or static rope is sufficient for window cleaning, in general, the less stretch, the better. Rope descent work is fairly forgiving of stretch, but when you try to come to a stop, the less stretch, the less you'll bounce. Stretch becomes more important in ascending a rope or hauling (think about lifting an injured person in a rescue). The stretchier the rope, the harder you have to work since you lose a bit of your effort to stretch. That's why dynamic rope isn't suitable for industrial work.

Diameter

| Rope Size |

|

7/16" = 11-11.5mm 1/2" = 12.5-13mm 5/8" = 16mm |

The diameter of the rope refers to its thickness. There are three common sizes you'll find for high rise window washing:

7/16" - 11-11.5mm

½" - 12.5-13mm

⅝" - 16mm

The diameter you choose has significant consequences. First, it affects the strength of the rope. All things being equal, a thicker rope is stronger. So, for example, ½" KMIII is stronger than 7/16" KMIII. Secondly, the diameter will affect the weight of the rope. The thicker the rope, the heavier it is per foot, increasing the total weight you'll have to carry to a job site. For many crews, this is a strong incentive to go with thinner diameter rope.

Lastly, and arguably most importantly, the rope's diameter (along with construction and possibly manufacturer's guidelines) dictates what gear it is compatible with. If you are convinced that the Petzl ID is the best descender for you, getting ⅝" rope won't be an option. Before making a final selection, consider which rope grab and descender you'll use and make sure to get the rope that matches.

Many people have the mindset that the stronger the better, so why not get the thickest rope available? There's certainly nothing wrong with this, but remember that thicker rope is heavier and could limit devices used. Also, remember that a common regulatory strength requirement is to have a 5,000 lbf MBS. Once you've exceeded that, your rope is more than strong enough for virtually any rope descent work that you might do. 7/16" KMIII, for example, has an MBS of 7,900 lbf. Even after tying most knots, it's still well over 5,000 lbf.

Color

For rope descent, color doesn't make any functional difference. Black, orange, or white KMIII will all act the same, with the same performance, hand, stretch, etc. Color is useful if your company color codes equipment. For example, some companies use 7/16" rope for their main lines and ½" rope for their backup lines. The two sizes can be challenging to tell apart, so color-coding your diameters can be helpful. Other companies assign specific gear to different cleaners, so color-coding can help keep track of who has what.

In other industries such as mining and cave rescue, color is helpful for communication. When you are out of sight from someone else, it's easier to give instructions like "let out slack on the green rope" than it would be to identify the ropes in another way.

White is by far the most popular color rope. Why? Because it's the least expensive. All other colors of rope go through an extra manufacturing step to dye, which adds cost. For most ropes, white is one price, and all other colors are another price.

Certifications

Interestingly, rope certification comes up far less than with other devices. abc frequently converses with customers concerning the certification of carabiners, rope grabs, descenders, etc. But this doesn't seem to be the issue with rope.

There are a variety of European certifications that don't apply to the US. The two that do matter for rope are NFPA and ANSI.

NFPA is the National Fire Protection Association. It's generally a standard for firefighters but also has applications in rope access, rescue, and rope descent. For NFPA 1983, rope is broken into NFPA Technical (T), which requires a rope to have a 22kN (5,000 lbf) MBS, and NFPA General (G), which requires a 40kN (~9,000 lbf) MBS. Often, you'll find that 7/16" ropes are NFPA T and ½" ropes are NFPA G. Note that being strong enough doesn't automatically mean that a rope is certified as NFPA. It must be certified by a third party.

The American National Standard Institute (ANSI) is the most common standard found in industrial work, including window cleaning and rope descent. Curiously, very few ropes are ANSI certified. Beyond having your rope be compatible with other devices that you choose and that rope meeting the same general guidelines as all of your gear (be able to support 5,000 lbf, for example), we are unaware of any specific ANSI requirements for rope. That's probably why most ropes aren't ANSI certified since there isn't a specific requirement for testing. However, a few ANSI stamped ropes do exist, although they are rare.

For most high rise window cleaners, the essential factors to keep in mind are ensuring that the rope is suitable in terms of strength and compatibility, along with being NFPA certified.

Photo Credit: Jimmy Keithley, Outlook Window Cleaning, Utah. Photographer Jon Vickers

Disclaimer

Information on this page was last updated on 04/26/2021. For the latest information, refer to manufacturer's instructions. Any information provided by abc is intended to help you decide which gear will work for you and is not a substitute for proper training and your evaluation of specific work site conditions. Work at height is inherently dangerous. User accepts full responsibility for the use of this and any other safety equipment. ABC OFFERS NO EXPRESS WARRANTIES AND DENIES THE EXISTENCE OF ANY IMPLIED WARRANTIES. ANY WARRANTIES WITH RESPECT TO THE PRODUCTS SOLD ARE PROVIDED BY THE MANUFACTURER.